This article is the first of a series of articles where we presented case studies from the author own projects’ experience. We have recently presented these case studies as a workshop; part of a Project Management Conference (PM360) in Singapore that was organized by Knowledge Method, sponsored by RMC Project Management, and supported by SUKAD and two other partners.

Project Management Case Study 1

Project Characteristics

Project Characteristics

- Mega Project: approved budget was about (~) $700 million US (early 1990’s).

- This mega project had two main sub-projects

- One sub-project was modifications to an existing refinery (~$100 million), and

- The second sub-project (~$600 million) was new facilities (grass roots/green field)

- Project was on an Island, in a country where there were limited labor and technicians.

The Project Owner

- The Project Owner was a joint venture consisting of three companies:

- 50% (N. America),

- 40% (N. America),

- 10% (Asia)

- The 10% company was a joint venture between the 40% company and a government of an Asian country.

The Service Providers

- Project Owner awarded a global contractor (main contractor) an Engineering, Procurement, and Construction (EPC) contract

- Contract was reimbursable (cost-plus), incentive contract

- Main contractor was ultimately responsible for engineering, procurement, and construction management (UK); construction was to be awarded to a construction general contractor

- Construction general contractor, ended up being a joint venture between three companies (Europeans – mostly Germans)

- Construction labor came from Asian countries, senior construction staff were mostly European and Asian

Project Management

- The Project Owner, through their project management departments, was responsible for the

overall management of the project (program)

overall management of the project (program) - Most project management team members and operation representatives came from the main partner but with a few resources from the other partners

- The owner project management team members came mostly from North America, but we also had European and Asian members

- The owner project management team was geographically split between Europe (UK) and S.E. Asia (more than one location)

- Because of the cost-plus – incentive contract, the project owner delegated some of the project management activities to the main contractor

Global Project

- The Project Owner’s executive management and main offices were in North America (the minority partner was in Asia)

- Project management team was split and working from more than one location

- The engineering activities were mostly performed in the UK

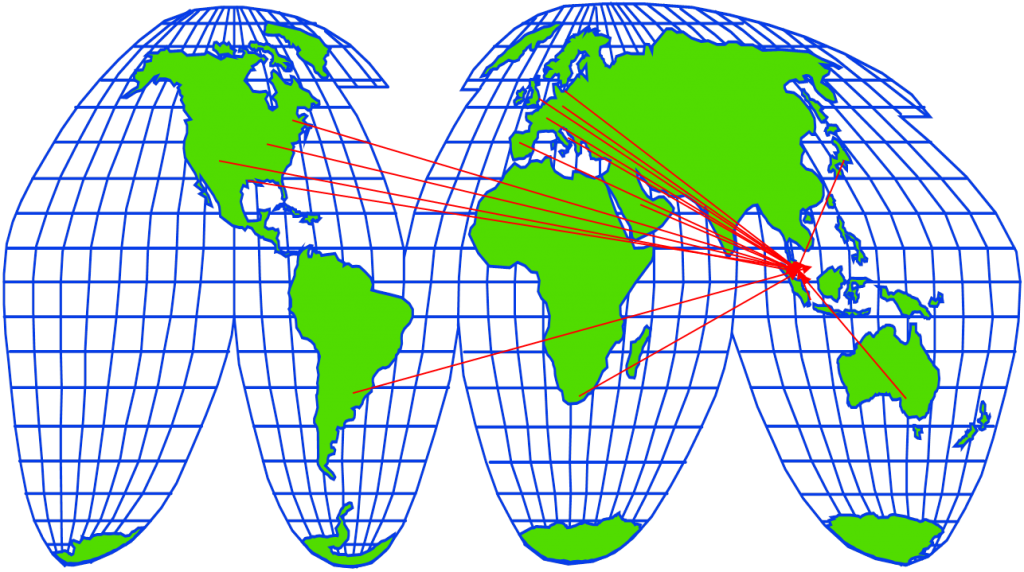

- Procurement was led from the UK but with global sourcing (see figure)

- All materials and equipment had to be shipped to one of four construction locations in SE Asia

- Construction was on four sites; most of the work on two of the four sites

- The Service Providers’ construction management members were mostly European and Asian but included other nationalities

- Construction supervision staff were also international

- Labors were mostly Asian

Challenges and Success Factors (Focus on Human Aspects)

- Large number of organizations (3 project owners, main contractor, 3 construction companies (joint venture), 4 construction sites, multiple vendors and subcontractors … In this case, the challenges were among the partners’ organizations (Project Owner); in addition to the normal challenges between Project Owner and Service Provider. The above was the main challenge, which encouraged us to split our project management teams across all sites but develop close working, although virtual, relations. For the partners, we work as integrated teams – in transparency, which enhanced the trust. In regard to owner/contractor challenge, the Project Owner and main contractor project management teams worked in a semi-integrated approach (could not fully integrate). Again the key was transparency and fairness in the approach, looking for win-win, and open and timely communication.

- Global locations and spreading the team were challenges: We had to overcome through frequent online and face to face communications; although this was before social media, BBM, and smart phones. We had regular team meetings, email communications, management monthly reports, and quarterly face-to-face meetings that included owner and contractor’s personnel.

- Island location, limited space, and limited resources: Solution was modular construction and four construction sites (another case study). Splitting the construction work among multiple sites helped us avoid the island space limitations and labor issues. Further, by going to fabrication yards, we were able to enhance safety and workforce productivity.

- Early in the project, the incentive-cost plus contract was a challenge (almost a threat) and created conflict; since the budget was set by the owner: We had to resolve the conflict as soon as possible; through open communication and educational sessions on the owner budgeting and estimating processes. Further, as we learned to work together, we learned to trust each other … because of the incentives, the contract type became an advantage (opportunity)

- Language was a key issue especially in construction (Safety): Resolved by ensuring all construction sign and safety messages were available in four languages … and each crew had a foreman who speaks one of the four languages. We also used a decent deal of pictures and illustrations.

- Labor was not used to strict North American construction safety rules: Resolved by making every project management team member safety aware and proactive; including daily site walk-through. We also used innovative training techniques with the labors; including using Models to teach them how to use and wear proper protective clothing.

SUKAD offers learning program for capital investment (intensive) projects such as the one discussed in this case study. These learning programs include PM Case Studies, Managing Project Success, Project Management for the Capital Intensive Projects, Project Management for Oil & Gas, Project Change Management for Capital Projects, Project Control for Managers, Project Control Workshop … among many others.

SUKAD offers learning program for capital investment (intensive) projects such as the one discussed in this case study. These learning programs include PM Case Studies, Managing Project Success, Project Management for the Capital Intensive Projects, Project Management for Oil & Gas, Project Change Management for Capital Projects, Project Control for Managers, Project Control Workshop … among many others.

We also provide organizational and consultancy solutions for these types of projects. These solutions include implementing project management office (PMO), project support office, project reviews, project control services, clients’ representative, and even full outsourcing solutions for small and medium size enterprises.

We also provide organizational and consultancy solutions for these types of projects. These solutions include implementing project management office (PMO), project support office, project reviews, project control services, clients’ representative, and even full outsourcing solutions for small and medium size enterprises.

This comment is By Luis Claudio, MBA on LinkedIn:

Very insightful article on project management across national and linguistic obstacles, having a lot of recent PM experiences with Latin American projects, I can attest to the differences in language, national and cultural obstacles that these issues present. It is up to the project manager to find a way to deal with these issues and transform the obstacles into learning opportunities. In the end, these achievements are golden nuggets in your lessons learned archives and can serve to institutionalize learning throughout the organization. I really enjoyed your article and more than appreciated your challenges

Mr. Claudio

Thank you for the kind words. Indeed challenges like these are great learning opportunities and these challenges are also universal. Thank you for sharing.

Mr. Mounir,

It is a great article describing the Global Delivery and constraints.

I feel the most interesting portion in the blog was to perceive the cost plus incentive model as an opportunity in building the trust and relationship with the owner. I’m sure similar such model was percolated down the line while handling the labors.

I believe the team might have used a robust scheduling and tracking software (like Primavera) in those days! I think MS project footprint was not there in those days. In current scenario it’s smooth as we have the option of such artefacts hosted in cloud and team at all locations can collaborate to achieve the desired deadline. I would like to know how the team handled different time zone while communicating live with each other.

I liked this article very much and also the comments made by Mr. Claudio.

Dear Mr. Rakshit

Thank you for the contribution.

Yes – project of that size would typically use Primavera for scheduling – although at the time MS Project was there and we used it internally (client’s team) but for the EPC work it had to be Primavera.

In general cost plus incentive contracts are not common but they are good for building relations – much less confrontational than fixed price!

Regards