This article is the second of a series of articles where we presented case studies from the author own projects’ experience. We have recently presented these case studies as a workshop; part of a Project Management Conference (PM360) in Singapore that was organized by Knowledge Method, sponsored by RMC Project Management, and supported by SUKAD and two other partners.

This article is the second of a series of articles where we presented case studies from the author own projects’ experience. We have recently presented these case studies as a workshop; part of a Project Management Conference (PM360) in Singapore that was organized by Knowledge Method, sponsored by RMC Project Management, and supported by SUKAD and two other partners.

Project Management Case Study 2

Project Characteristics

- Mega Project: approved budget was about (~) $700 million US (early 1990’s).

- This mega project had two main sub-projects

- One sub-project was modifications to an existing refinery (~$100 million), and

- The second sub-project (~$600 million) was new facilities (grass roots/green field)

- Project was on an Island, in a country where there were limited labor and technicians.

The Project Owner

- The Project Owner was a joint venture consisting of three companies:

- 50% (N. America),

- 40% (N. America),

- 10% (Asia)

- The 10% company was a joint venture between the 40% company and a government of an Asian country.

The Service Providers

- Project Owner awarded a global contractor (main contractor) an Engineering, Procurement, and Construction (EPC) contract

- Contract was reimbursable (cost plus), incentive contract

- Main contractor was ultimately responsible for engineering, procurement, and construction management (UK); construction was to be awarded to a construction general contractor

- Construction general contractor, ended up being a joint venture between three companies (Europeans – mostly Germans)

- Construction labor came from Asian countries, senior construction staff were mostly European and Asian

Major Challenges

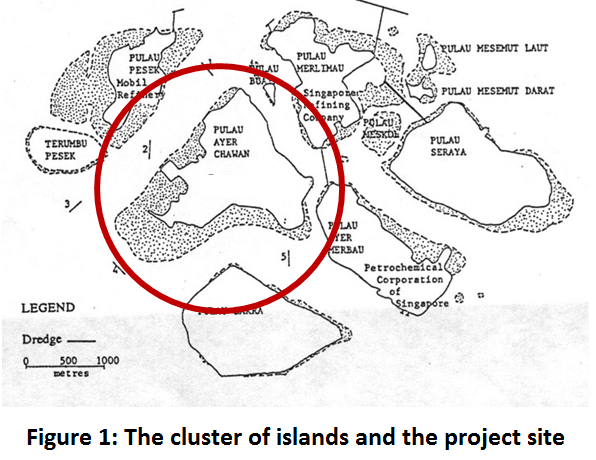

- Project was on a small island, with an existing refinery, and limited space for the new plant. As a

result, we had to reclaim land from the sea to increase the plot space.

result, we had to reclaim land from the sea to increase the plot space. - The government wanted to connect all of these islands (see figure) into one large island; reclamation was ongoing while our project was in progress; which means we had to finish before they close the shipping channel on us.

- Another difficult challenge was the lack of qualified labors in the area, which we would have to bring from other countries and this led to another problem: housing them.

- A typical project of this size would require more than 5000 people on site, which was not possible in our case

Possible Solutions

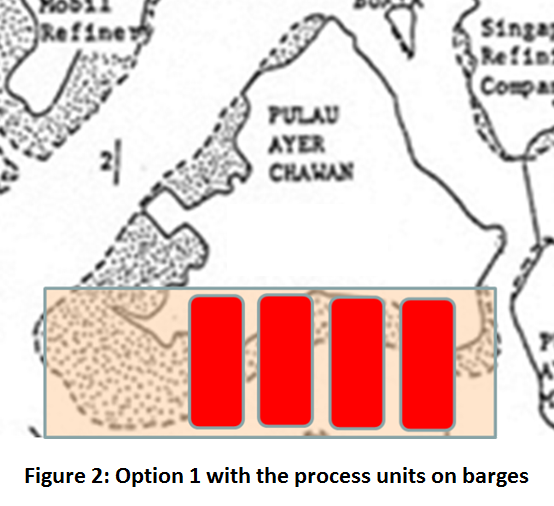

Option 1

- Build the plant’s main process units on barges,

- Float the barges to a partially prepared site,

- Build a dike around them,

- Fill the barges with concrete to settle them on the shallow sea floor

- Fill around them (reclaim from the sea)

- Build the rest of the facilities around them.

Option 2

- Use modular construction techniques,

- Build the main process units as modules at fabrication yards in the region,

- Ship them to the site on barges,

- Install them one after the other – like Lego,

- This was the selected option,

- Resulted in close to 200 modules, including:

- Process units module (2nd picture below),

- Pipe racks modules (1st picture below),

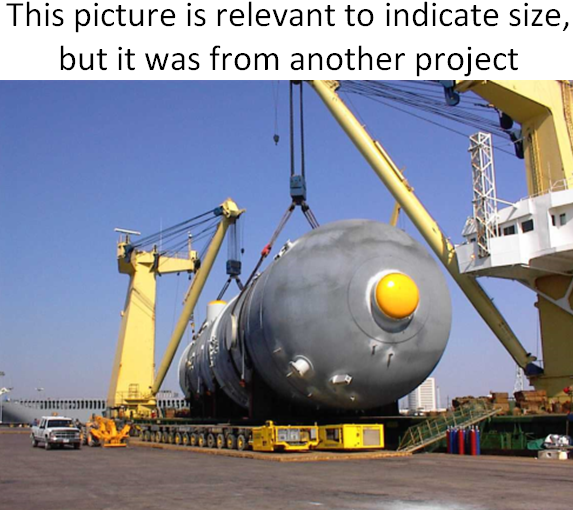

- Large vessels modules (similar to the 3rd picture) but in our case the vessels came with insulation, paint, pipe, instruments, electrical, etc., already installed.

- Many of the modules were the size of a four-story building, which required heavy lifts

Secondary Risks

- The above solutions solved the challenges of the island limited space and labors but created numerous other challenges,

- The team felt the other challenges are manageable, and accepted them

- Some of these secondary risks were:

- Shipping risks

- Installation risks; safety, fabrication defects, construction sequencing …

- Splitting the management team; multiple locations

- Availability of crane large enough to lift the modules; had to book in advance

The Project Results

- Despite the challenges, the project was considered successful in term of:

- Success of the product,

- Success of project management, and

- Overall success of the product delivery

- Business success is another subject and outside this case study

- The modular concepts worked well with minimal issues although, not without challenges

SUKAD offers learning programs for capital investment (intensive) projects such as the one discussed in this case study. These learning programs include PM Case Studies, Managing Project Success, Project Management for the Capital Intensive Projects, Project Management for Oil & Gas, Project Change Management for Capital Projects, Project Control for Managers, Project Control Workshop … among many others.

SUKAD offers learning programs for capital investment (intensive) projects such as the one discussed in this case study. These learning programs include PM Case Studies, Managing Project Success, Project Management for the Capital Intensive Projects, Project Management for Oil & Gas, Project Change Management for Capital Projects, Project Control for Managers, Project Control Workshop … among many others.

We also provide organizational and consultancy solutions for these types of projects. These solutions include implementing project management office (PMO), project support office, project reviews, project control services, clients’ representative, and even full outsourcing solutions for small and medium size enterprises.

We also provide organizational and consultancy solutions for these types of projects. These solutions include implementing project management office (PMO), project support office, project reviews, project control services, clients’ representative, and even full outsourcing solutions for small and medium size enterprises.

This comment is By Paul Tiffany On LinkedIn:

If you want to share what you’ve learned in this group blog environment, don’t hold back. Give us the key points of what you’ve learned. What you wrote tells me nothing and gives me no incentive to try and figure out what you already know and why I would want to read it. The project management library of resources is vast. We’re here in these groups to share the nuggets of what we’ve learned.

This comment is By Mounir Ajam On LinkedIn:

Hello Paul

Fair comment

This is a case study that describe a challenge and how we dealt with it. Although it is not specifically a lesson learned case.

The learning from this case study is primarily to counter a point often made that project management is restrictive and does not allow for innovation. Here is a situation with a mega project and challenging construction environment.

What I have learned, beside innovative approaches, is how to deal with complexity of engineering and constructing a world-scale petrochemical plant through a modular construction approach where sequencing of engineering, assembly and construction is critical for project success. We learned how to take care of the critical details that are easily missed to ensure safe and workable solution.

From this specific projects there are numerous case studies – each is addressing a different element. The first one dealt with working across organizations and global locations. This is the second one – and next we will publish one about stakeholders involvement in a project control initiative.

Maybe I am still missing something – or I do not fully understand what a case study should do so I am still missing something please let me know. Remember in 1000 words or so – we are trying to explain something that can take 2 hours of discussions.

Once again – I appreciate your candid feedback